Jaw Couplings

Our jaw couplings deliver proven performance at a competitive price - perfect for pumps, conveyors, compressors, and general machinery where you need reliable torque transmission with minor shaft misalignment, shock absorption, and vibration damping.

Built from just three parts: two precision-machined cast iron or steel hubs with interlocking jaws, and a flexible elastomeric spider that snaps securely between them. This clean, straightforward design transmits power efficiently, cushions impacts and vibrations, and remains fail-safe—if the spider wears out, the jaws still engage to maintain drive until you replace it.

Spider Material (In Stock)

We currently stock urethane spiders only. Urethane delivers about 50% more torque capacity than standard nitrile in the same size, with superior resistance to oils, chemicals, and abrasion. It offers good damping while handling higher loads in compact setups. Temperature range: -30°C to +160°F (-34°C to +71°C).

(Nitrile for maximum damping or Hytrel for extreme torque/temperature available on request.)

Bore Options

- Standard bores are available in precise 0.0625-inch increments from minimum to maximum, typically including keyways and set screws where specified.

- Larger sizes (110 through 276) are supplied plain (without keyway or set screws) for versatility.

- Custom machining options include plain bores, splines, hex configurations, metric sizes, or other specialized shaft requirements.

For detailed torque ratings, dimensions, and specifications, refer to the tables below.

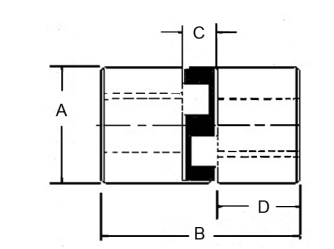

Dimensions

| Catalog Number | Hub Dia (A) | Overall Length (B) | Distance Between Flanges (C) | Length Thru Bore (D) | Bore Min | Bore Max | Approx Weight (lb) |

|---|

| L035 | 0.625 | 0.813 | 0.281 | 0.266 | 0.125 | 0.375 | 0.1 |

| L050 | 1.167 | 1.719 | 0.469 | 0.625 | 0.25 | 0.625 | 0.1 |

| L070 | 1.375 | 2 | 0.5 | 0.75 | 0.25 | 0.75 | 0.3 |

| L075 | 1.75 | 2.125 | 0.5 | 0.813 | 0.25 | 0.875 | 0.4 |

| L090 | 2.125 | 2.125 | 0.5 | 0.813 | 0.25 | 1.125 | 0.7 |

| L095 | 2.125 | 2.5 | 0.51 | 0.438 | — | 1.125 | 0.8 |

| L099 | 2.531 | 2.875 | 0.75 | 1.067 | 0.5 | 1.375 | 1.2 |

| L100 | 2.531 | 3.5 | 0.75 | 1.375 | 0.438 | 1.375 | 1.5 |

| L110 | 3.313 | 4.25 | 0.875 | 1.688 | 0.5 | 1.625 | 3.2 |

| L150 | 3.75 | 4.5 | 1 | 1.75 | 0.625 | 1.875 | 4.5 |

| L190 | 4.5 | 4.875 | 1 | 1.938 | 0.75 | 2.125 | 8.3 |

| L225 | 5 | 5.375 | 1 | 2.188 | 0.75 | 2.625 | 12 |

| L276 | 6.187 | 7.813 | 1.5 | 3.12 | 0.875 | 2.875 | 30.5 |

Performance Data

| Catalog Number | Max RPM | Torque (in-lb) | HP @ 100 RPM | HP @ 1200 RPM | HP @ 1800 RPM | HP @ 3600 RPM |

|---|

| L035 | 31000 | — | — | — | — | — |

| L050 | 18000 | 39 | 0.06 | 0.75 | 1.1 | 2.3 |

| L070 | 14000 | 65 | 0.1 | 1.2 | 1.8 | 3.8 |

| L075 | 11000 | 135 | 0.21 | 1.7 | 2.6 | 5.1 |

| L090 | 9000 | 216 | 0.35 | 2.7 | 4.1 | 8.2 |

| L095 | 8000 | 291 | 0.47 | 3.7 | 5.5 | 11 |

| L099 | 7000 | 477 | 0.77 | 6 | 9.1 | 18 |

| L100 | 7000 | 626 | 1 | 7.9 | 12 | 24 |

| L110 | 5000 | 1188 | 2 | 15 | 23 | 45 |

| L150 | 5000 | 1860 | 3 | 24 | 35 | 71 |

| L190 | 5000 | 2589 | 4.1 | 33 | 49 | 99 |

| L225 | 4600 | 3510 | 5.6 | 45 | 67 | 134 |

| L276 | 4200 | — | — | — | — | — |